RF and Hot Air Composite Bonding Systems

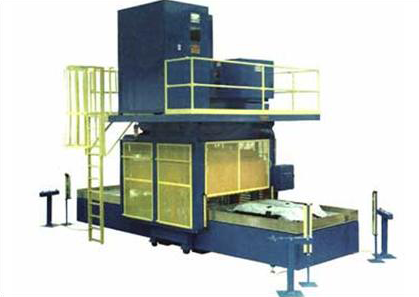

Hot Air Composite Bonder:

10-ton system supplies a resonating high-impingement air flow to produce very efficient and even thermal transfer. Adhesive is applied to parts, which are automatically positioned on press by robots. Adhesive is cured by hot air, followed by ambient air to strengthen bond while part is still clamped.

Composite Bonder:

System features a water-cooled RF generator to bond composite material at a rate of two parts per minute. This particular press was built to manufacture hoods for the Ford Mustang.